Exploring Off-Earth Manufacturing: Tech Companies See Big Benefits in Producing Drugs, Stem Cells and Crystals in Space

Key Highlights :

The new space race has been dominated by billionaires joyriding around in rockets, but behind the scenes, tech companies are looking to the first non-Earth production lines. With certain conditions in space, such as the lack of gravity, low temperatures and near-perfect vacuum, certain ingredients, such as crystals, can be made at a better quality than on land. Pharmaceutical companies are betting that new drugs can be made in space, and researchers at Bristol Myers Squibb are testing how to use resources built off-planet to make drugs easier to store.

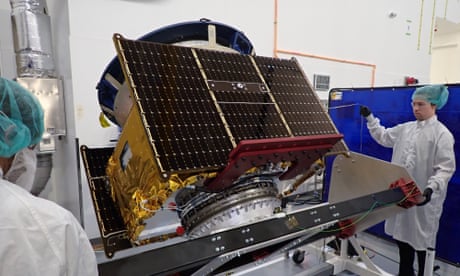

NASA has collaborated with commercial partners to enable off-Earth manufacturing since 2016, and the goal is to develop a “low-earth orbit” (Leo) economy that will strengthen the US’s leadership in the tech world. In July, the California-based startup Varda Space Industries launched a capsule into the earth’s orbit, intended to be a “space drugs factory”, which autonomously grew crystals of the drug ritonavir, an anti-viral medication used to treat HIV. However, the Federal Aviation Administration and the US air force denied Varda’s request to return to earth.

In 2031, the International Space Station will be decommissioned and plunged to a watery grave at the bottom of the Pacific. After that, NASA will rent space on commercial space vehicles instead, and the demand for in-orbit production will increase. Companies that produce off-planet say that the number of products produced in space will ramp up by the end of the decade, since they will no longer need to go solely through the ISS to get to space.

Humans can replicate some of space’s conditions on earth, but it costs a lot of money to build that kind of infrastructure. With the advent of more commercial space stations, the price and cost of going to space will come down significantly, and so will performing this kind of work. Shortly after the launch of their currently stuck drug factory, Varda’s co-founders spoke to CNBC about their lofty plans for manufacturing pharmaceuticals in space.

Tech companies are realizing the potential of off-Earth manufacturing, and are investing in research and development in microgravity to produce computer parts, harvest stem cells, produce pharmaceuticals and create crystals in space. With more privately owned shuttles in space, the larger the opportunities for off-earth factories become. The future of off-Earth manufacturing is bright, and it looks like it won’t be too long before we start seeing applications that are commercially viable.